Traffic and mobility analysis in elevator design at Everest Lift is one of the main tasks carried out in the elevator design process.

The nominal travel time and waiting time for the elevator must be considered in the design of the elevator, and the elevator’s capacity in terms of the number of people or cargo it can carry is very important in the design of the elevator.

One of the steps in designing an elevator is placing the elevator parts in the pit. Utilizing the maximum pit space after analyzing traffic is very important. It is also important to determine the dimensions of the cabin to be built and to be able to be installed and operated in the intended pit.

The most basic and main step before installing an elevator is to design, map, and analyze the traffic of the building and the elevator.

In the installation of an elevator, many factors such as the design and architecture of the building, the type of use of the building, the number of floors, the number of units on each floor, the amount of traffic, etc. will be effective, which play the most role in installing the best condition of the elevators.

In the initial design of the building, a part of the building is considered for the elevator, which is called the elevator shaft. After the roofs of the building are completed, it is the turn of the elevator company. Elevator companies visit the building for an initial visit and after taking various measurements such as: shaft width, shaft depth, travel length, door location, floor height, shaft depth, etc., they examine the values of these measurements and consider the best condition and type of elevator for the building.

One of the most important aspects of elevator design is traffic analysis.

Traffic analysis helps us choose the best number of elevators, elevator capacity, elevator speed, etc., all of which are important for passenger movement and reducing the waiting time for the elevator to arrive.

The percentage of the building’s population that can be moved by elevator in 5 minutes. In residential buildings, 5% of the building’s population can be moved in five minutes to ensure optimal movement between floors. This percentage should reach 12% in commercial buildings.

The result of dividing the nominal elevator travel time by the number of elevators is called the elevator wait. This time is acceptable in residential buildings up to 1.5 minutes, in office buildings this number should be around 35 seconds and ideally around 25 seconds.

Using the maximum pit space After analyzing the traffic, it is very important to know what dimensions the cabin can be built with and can be installed and operated in the intended pit. Of course, the more pit space is used and the less empty space is left in the pit, the better, because the more pit space is used, the larger the cabin size becomes.

It is the time it takes for the elevator to go from the highest floor to the lowest floor and return to its starting position.

Everest Lift offers its customers cabins with excellent construction quality and a very luxurious appearance. The beautiful design of the interior of the elevator cabin, using a variety of materials (including stainless steel, Formica, etc.) in the walls and false ceiling, as well as a variety of flooring (including stone, parquet, etc.), offers customers a very wide choice.

Everest Lift offers a wide variety of panoramic elevators based on the needs of architects and building engineers. Due to the remarkable beauty of the panoramic elevator, architects can use it as one of the important elements in architectural design.

In addition to providing beauty, stainless steel fully meets the sanitary conditions required in hospitals and medical centers.

Everest Lift has designed cargo cabins in such a way that, in addition to being highly resistant to impacts caused by cargo transportation, they can also carry loads of up to 12 tons. Such cabins are used in car elevators, industrial elevators, etc.

In special environmental conditions and with a high degree of protection, the elevator has a high IP and is also an industrial workshop elevator. This company, relying on the previous knowledge and engineering of its experts in the field of designing and producing various types of industrial elevators and workshop elevators, announces its readiness to provide services to esteemed employers in various industries of industrial and manufacturing factories. This company has implemented various projects in all fields of special elevators such as industrial elevators and workshop elevators.

And has a high degree of protection, the elevator has a high IP and is also an explosion-proof workshop elevator. This company, relying on the previous knowledge and engineering of its experts in the field of designing and producing various types of explosion-proof elevators, announces its readiness to provide services to esteemed employers in various industries such as oil and gas, industrial and manufacturing and chemical factories.

Moon Charge Everest Lift elevators have industrial and residential users for restaurants, libraries, coffee shops, etc.

Moon Charge Everest Lift elevators have industrial and residential users for restaurants, libraries, coffee shops, etc.

A roomless elevator is an elevator that does not have a separate space for the motor and control panel, and the motor is located in a pit under the ceiling and the panel is located next to the highest stop. These types of elevators are usually installed in buildings that have height restrictions or where an elevator with a stop on the roof is required.

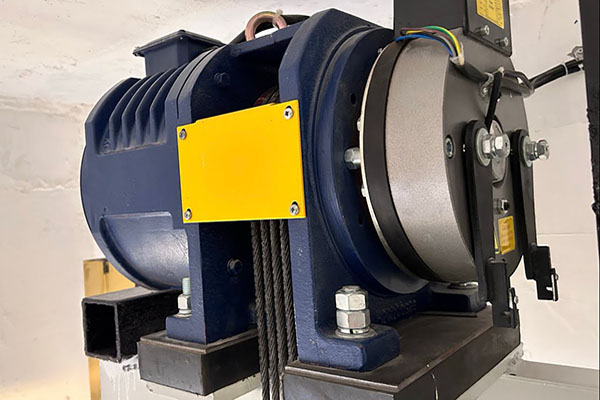

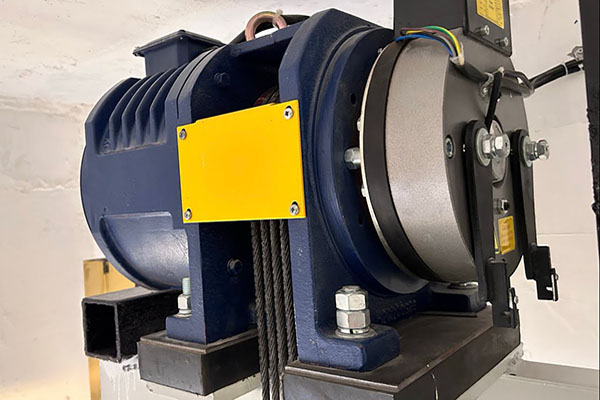

The motor used in roomless elevators must be of the gearless type, and the reason for this is that the volume of gearless motors is much smaller than that of gearboxes. In gearless systems that are implemented with and without a motor room, given that the suspension system is two to one, the rotation speed of the motor is twice the speed of the cabin. This means that if an elevator with a speed of 1 meter is required, in this case the motor must rotate at a speed of 2 meters per second.

The suspension system in roomless elevators is two to one. In two to one suspension systems, the fixing of the headboxes is fixed at the same level as the motor at the highest part of the elevator shaft, instead of being placed on the cabin and the weight. In this way, after fixing one side of the headboxes and passing over the weight idler pulleys, the motor pulley and then the cabin idler pulleys are closed again at the level of the motor base coil.

It is considered the latest technology in the elevator industry in the world. In this system, the speed change gearbox has been replaced by a speed change controller by reducing and increasing frequency and voltage. This new technology has reduced the volume of the drive system and has enabled the installation of the motor inside the elevator shaft. In this case, the motor room is removed from above the elevator duct, construction costs are reduced, and the possibility of stopping on the roof of the building becomes easy.

Gearless motor; Passengers in this model will experience much smoother and more comfortable starts and stops, the motor of this system will operate cooler and will not heat up due to its construction type, and even in traffic and heavy work conditions, the motor will not stop to cool down, in this motor the dimensions and weight are reduced, the gearless motor does not require lubrication, all parts of the elevator such as the motor, brake pads, and the cable will move smoothly, and as a result, their life will be longer.

Hydraulic elevators are another type of elevator that has advantages and disadvantages over traction elevators and is more efficient in certain situations. In this section, we will try to explain a few of these cases.

Hydraulic elevators, such as traction elevators, have a cabin, buffer shoes, and other parts. Their difference from traction elevators is in their motor or driving force. In hydraulic elevators, a jack is placed instead of the elevator motor and is moved by pumping oil by a part called the power unit, which causes the stage to open and the length of the jack to increase. The increase in the length of the jack will also cause the cabin to move upward. Also, when moving downward, the power unit cuts off the back pressure of the oil and allows the pumped oil to slowly return to the power unit and the cabin to move downward by the pressure of gravity and the weight applied to the jack head by the cabin.

To ensure uninterrupted elevator operation and receive fast and professional support services, contact us now.

The Everest Lift team is always ready to serve you with professional, transparent, and reliable services, along with 24/7 support.

The elevator design process includes an initial visit to the project site, calculating the appropriate capacity and speed, selecting the type of system (traction or hydraulic), designing technical drawings, locating equipment, and reviewing safety requirements and standards.

Yes. Elevator design depends on various factors such as building height, number of floors, number of units, building use (residential, commercial, office) and project budget. Each building requires a specific design.

In elevator design, national (ISIRI 6303 and 6303-1) and international (EN81, ISO) standards are followed. Municipal, fire department, and standards organization laws are also taken into account.

Depending on the complexity of the project, elevator design usually takes between 3 and 7 business days. For larger or special projects, this time may be slightly longer.

No. Elevator design is not only done for buildings under construction, but also for renovation and modernization projects of old elevators to improve system performance and increase safety.

The cost of elevator design depends on the size of the project, the type of elevator, the complexity of the architectural structure, and the specific needs of the employer. For detailed inquiries, it is recommended to contact our experts or complete the consultation request form.

Yes. After the design is finalized, technical files including executive drawings, electrical diagrams, component layouts, and dimensional details are provided to the client.

Yes. Our experts are ready to visit your project site and provide an initial consultation completely free of charge. Just contact us and arrange a time for the visit.

Traffic and mobility analysis in elevator design at Everest Lift is one of the main tasks carried out in the elevator design process.

The nominal travel time and waiting time for the elevator must be considered in the design of the elevator, and the elevator’s capacity in terms of the number of people or cargo it can carry is very important in the design of the elevator.

One of the steps in designing an elevator is placing the elevator parts in the pit. Utilizing the maximum pit space after analyzing traffic is very important. It is also important to determine the dimensions of the cabin to be built and to be able to be installed and operated in the intended pit.

The most basic and main step before installing an elevator is to design, map, and analyze the traffic of the building and the elevator.

In the installation of an elevator, many factors such as the design and architecture of the building, the type of use of the building, the number of floors, the number of units on each floor, the amount of traffic, etc. will be effective, which play the most role in installing the best condition of the elevators.

In the initial design of the building, a part of the building is considered for the elevator, which is called the elevator shaft. After the roofs of the building are completed, it is the turn of the elevator company. Elevator companies visit the building for an initial visit and after taking various measurements such as: shaft width, shaft depth, travel length, door location, floor height, shaft depth, etc., they examine the values of these measurements and consider the best condition and type of elevator for the building.

One of the most important aspects of elevator design is traffic analysis.

Traffic analysis helps us choose the best number of elevators, elevator capacity, elevator speed, etc., all of which are important for passenger movement and reducing the waiting time for the elevator to arrive.

The percentage of the building’s population that can be moved by elevator in 5 minutes. In residential buildings, 5% of the building’s population can be moved in five minutes to ensure optimal movement between floors. This percentage should reach 12% in commercial buildings.

The result of dividing the nominal elevator travel time by the number of elevators is called the elevator wait. This time is acceptable in residential buildings up to 1.5 minutes, in office buildings this number should be around 35 seconds and ideally around 25 seconds.

Using the maximum pit space After analyzing the traffic, it is very important to know what dimensions the cabin can be built with and can be installed and operated in the intended pit. Of course, the more pit space is used and the less empty space is left in the pit, the better, because the more pit space is used, the larger the cabin size becomes.

It is the time it takes for the elevator to go from the highest floor to the lowest floor and return to its starting position.

It offers its customers a great and luxurious appearance. The beautiful design of the elevator cabin, using a variety of materials (including stainless steel, Formica, etc.) in the walls and false ceiling, as well as a variety of flooring (including stone, parquet, etc.), offers customers a wide range of choices.

Everest Lift offers a wide variety of panoramic elevators based on the needs of architects and building engineers. Due to the remarkable beauty of the panoramic elevator, architects can use it as one of the important elements in architectural design.

In addition to providing beauty, stainless steel fully meets the sanitary conditions required in hospitals and medical centers.

Everest Lift has designed cargo cabins in such a way that, in addition to being highly resistant to impacts caused by cargo transportation, they can also carry loads of up to 12 tons. Such cabins are used in car elevators, industrial elevators, etc.

In special environmental conditions and with a high degree of protection, the elevator has a high IP and is also an industrial workshop elevator. This company, relying on the previous knowledge and engineering of its experts in the field of designing and producing various types of industrial elevators and workshop elevators, announces its readiness to provide services to esteemed employers in various industries of industrial and manufacturing factories. This company has implemented various projects in all fields of special elevators such as industrial elevators and workshop elevators.

And has a high degree of protection, the elevator has a high IP and is also an explosion-proof workshop elevator. This company, relying on the previous knowledge and engineering of its experts in the field of designing and producing various types of explosion-proof elevators, announces its readiness to provide services to esteemed employers in various industries such as oil and gas, industrial and manufacturing and chemical factories.

Atlas Elevator’s moon charge elevators have industrial and residential users for restaurants, libraries, coffee shops, etc.

Traction elevators are a type of elevator that is very common today. Traction elevators are driven by a driving force and ropes. Here we try to introduce you to how traction elevators work.

The first traction elevator was invented by a person named Alisha Otis. This was not the first lifting device, but Otis’s invention had a more modern form with a safety brake, which is like the current traction elevators.

Like most other elevators, traction elevators have a cabin, a weight, a driving force, a rope, a control panel, etc.

First of all, all traction elevators have one thing in common, and that is to have a weight frame that, like a seesaw, moves next to the elevator cabin, causing the cabin to move.

A roomless elevator is an elevator that does not have a separate space for the motor and control panel, and the motor is located in a pit under the ceiling and the panel is located next to the highest stop. These types of elevators are usually installed in buildings that have height restrictions or where an elevator with a stop on the roof is required.

The motor used in roomless elevators must be of the gearless type, and the reason for this is that the volume of gearless motors is much smaller than that of gearboxes. In gearless systems that are implemented with and without a motor room, given that the suspension system is two to one, the rotation speed of the motor is twice the speed of the cabin. This means that if an elevator with a speed of 1 meter is required, in this case the motor must rotate at a speed of 2 meters per second.

سیستم تعلیق در آسانسورهای روملس به صورت دو به یک میباشد. در سیستم های تعلیق دو به یک فیکسینگ سربکسل ها به جای اینکه روی کابین و وزنه قرار بگیرند هم تراز موتور در بالاترین قسمت چاله آسانسور فیکس میشوند. به این صورت که پس از فیکس کردن یکطرف سربکسل ها و عبور از روی فلکه های هرزگرد وزنه، فلکه موتور و سپس فلکه های هرزگرد کابین مجددا در تراز کلاف پایه موتور بسته می شوند.

It is considered the latest technology in the elevator industry in the world. In this system, the speed change gearbox has been replaced by a speed change controller by reducing and increasing frequency and voltage. This new technology has reduced the volume of the drive system and has enabled the installation of the motor inside the elevator shaft. In this case, the motor room is removed from above the elevator duct, construction costs are reduced, and the possibility of stopping on the roof of the building becomes easy.

Gearless motor; Passengers in this model will experience much smoother and more comfortable starts and stops, the motor of this system will operate cooler and will not heat up due to its construction type, and even in traffic and heavy work conditions, the motor will not stop to cool down, in this motor the dimensions and weight are reduced, the gearless motor does not require lubrication, all parts of the elevator such as the motor, brake pads, and the cable will move smoothly, and as a result, their life will be longer.

Hydraulic elevators are another type of elevator that has advantages and disadvantages over traction elevators and is more efficient in certain situations. In this section, we will try to explain a few of these cases.

Hydraulic elevators, such as traction elevators, have a cabin, buffer shoes, and other parts. Their difference from traction elevators is in their motor or driving force. In hydraulic elevators, a jack is placed instead of the elevator motor and is moved by pumping oil by a part called the power unit, which causes the stage to open and the length of the jack to increase. The increase in the length of the jack will also cause the cabin to move upward. Also, when moving downward, the power unit cuts off the back pressure of the oil and allows the pumped oil to slowly return to the power unit and the cabin to move downward by the pressure of gravity and the weight applied to the jack head by the cabin.

To ensure uninterrupted elevator operation and receive fast and professional support services, contact us now.

The Everest Lift team is always ready to serve you with professional, transparent, and reliable services, along with 24/7 support.

The elevator design process includes an initial visit to the project site, calculating the appropriate capacity and speed, selecting the type of system (traction or hydraulic), designing technical drawings, locating equipment, and reviewing safety requirements and standards.

Yes. Elevator design depends on various factors such as building height, number of floors, number of units, building use (residential, commercial, office) and project budget. Each building requires a specific design.

In elevator design, national (ISIRI 6303 and 6303-1) and international (EN81, ISO) standards are followed. Municipal, fire department, and standards organization laws are also taken into account.

Depending on the complexity of the project, elevator design usually takes between 3 and 7 business days. For larger or special projects, this time may be slightly longer.

No. Elevator design is not only done for buildings under construction, but also for renovation and modernization projects of old elevators to improve system performance and increase safety.

The cost of elevator design depends on the size of the project, the type of elevator, the complexity of the architectural structure, and the specific needs of the employer. For detailed inquiries, it is recommended to contact our experts or complete the consultation request form.

Yes. After the design is finalized, technical files including executive drawings, electrical diagrams, component layouts, and dimensional details are provided to the client.

Yes. Our experts are ready to visit your project site and provide an initial consultation completely free of charge. Just contact us and arrange a time for the visit.