When planning an elevator renovation, most companies usually focus on the operational aspects of the equipment. New technologies and products are usually designed to make elevators more reliable, safer, and faster. Many elevator companies specialize in these areas. They are trained in the mechanical and electrical aspects of the equipment. However, when it comes to aesthetics, many of them hire outside contractors to do the work for them. This is mainly due to the complexities of upgrading, planning, and coordination. But pre-engineered car solutions take the complexity out of car renovation. Elclip is a patented pre-engineered solution that eliminates the complexity and risks associated with car upgrades.

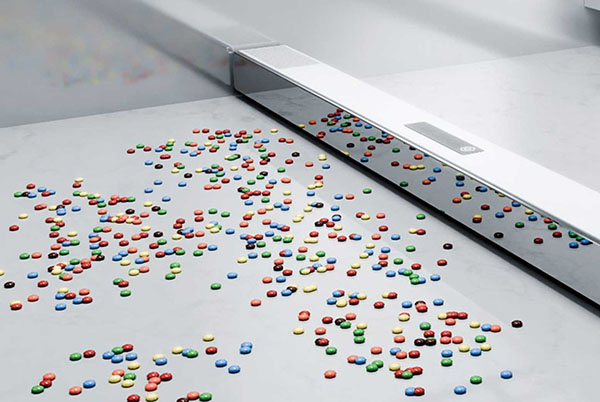

Pre-engineered solutions are designed as a system that works with a variety of existing car shell types. They are available in a variety of panel layouts and finishes. Installations require minimal measuring and can be completed in less than a day. When upgrading existing elevator finishes, several factors must be considered:

Weight

Materials that meet codes

Proper connections

Durability

Ease of installation

Material weight is a critical factor when considering car finishes. Regardless of the type of operation, weight affects performance, reliability and safety. Installers must consider how much weight will be removed and how much will be reinstalled. Any changes must be evaluated to determine the impact on the equipment and what steps need to be taken to mitigate the weight changes. New materials and installation methods are now available to reduce the weight of the installed materials while maintaining the same appearance.

Any new materials installed must be evaluated to verify compliance with codes. Flame spread and smoke development of materials are critical factors in selecting the materials to be installed in an elevator.

Common materials used in cabin finishes include metals, wood, glass and plastic. All should be assessed for compliance as well as the method of installation. In addition, lighting should be assessed to confirm that it meets minimum lighting requirements. New ceilings should be designed to allow access to the existing escape hatch regardless of location.

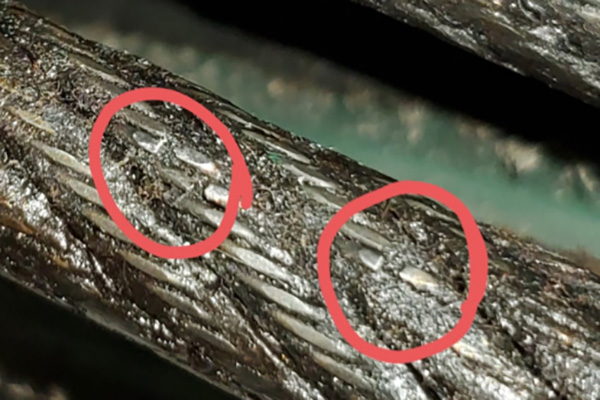

Most initial cabin installations have materials that are secured before the cabin is installed. Since cabin renovations use the existing shell and canopy, finishes usually have to be done from inside the cabin. This can create issues with alignment, proper connection and critical measurements. Pre-engineered systems use technologies that provide flexibility and ease of installation. The Eleclip system is designed with a clamp as part of the installation detectors. By installing the detectors in pre-determined locations, one simply clips the panels and locks them in place, all from inside the cabin with minimal effort and hidden connections. Furthermore, replacing the panels in the future, if required, can be done quickly and easily.